Other Topics That Might Interest You

See all

Replace HCL Notes? Migrate applications future-proof with Axon Ivy

End of Support for HCL Notes 9.x and 10.x: A Strategic Turning Point The discontinuation of support for HCL Notes versions ...

Read more

When HR Systems Spiral Out of Control: 5 Clues and Executive Fixes

Despite digital tools, many HR teams are stuck in silos, drowning in manual work, and cut off from the insights they need. ...

Read more

Orchestration of Business Processes

In today's fast-paced business world, companies face increasing complexity in their IT structures and business ...

Read more

News

31

Oct

24

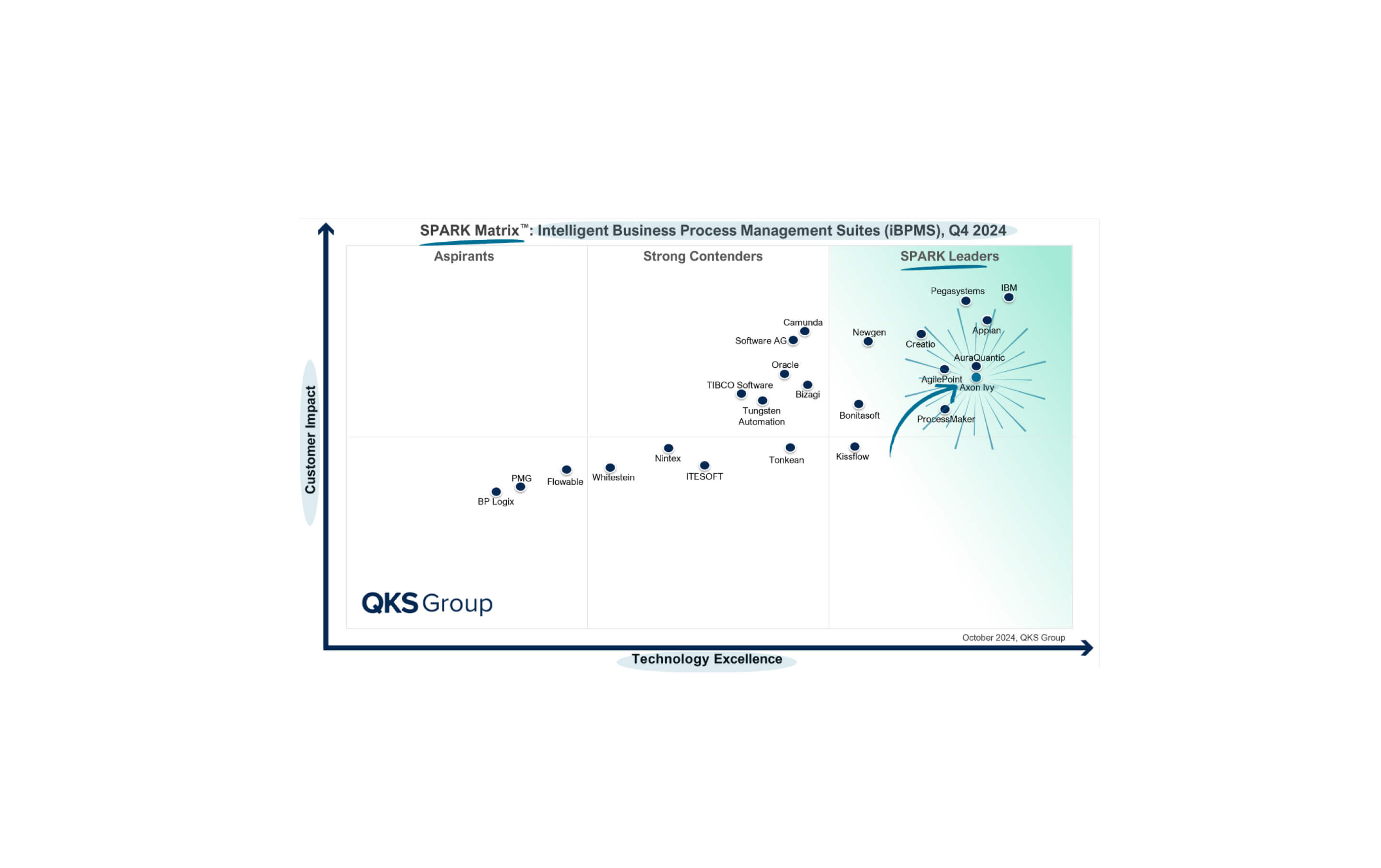

Axon Ivy Recognized as Leader in 2024 SPARK Matrix Report

We are delighted to announce that the QKS Group has positioned Axon Ivy as a Leader in their latest SPARK Matrix™ Report ...

Read more

Business Orchestration & Automation Technologies: Riding Every Wave with BOAT

Higher, further, faster – new technologies are advancing at breakneck speed and business demands are higher than ever. To ...

Read more