Other Topics That Might Interest You

See all

Digital Process Excellence: Why Market Leaders Go Beyond the Standard

Uncover hidden efficiency killers: Why standard software slows you down—and how smart automation puts your business back ...

Read more

News

15

Sep

25

Solving for Complexity: Axon Ivy’s Approach to Real-World IPO

In an era where automation alone no longer delivers a decided strategic advantage, enterprises are shifting their focus ...

Read more

Going Digital Isn’t Enough: Why HR Still Falls Behind

The Challenge: According to McKinsey, 60% of HR resources are tied up in manual tasks, leaving only 10% for strategic ...

Read more

News

29

Aug

25

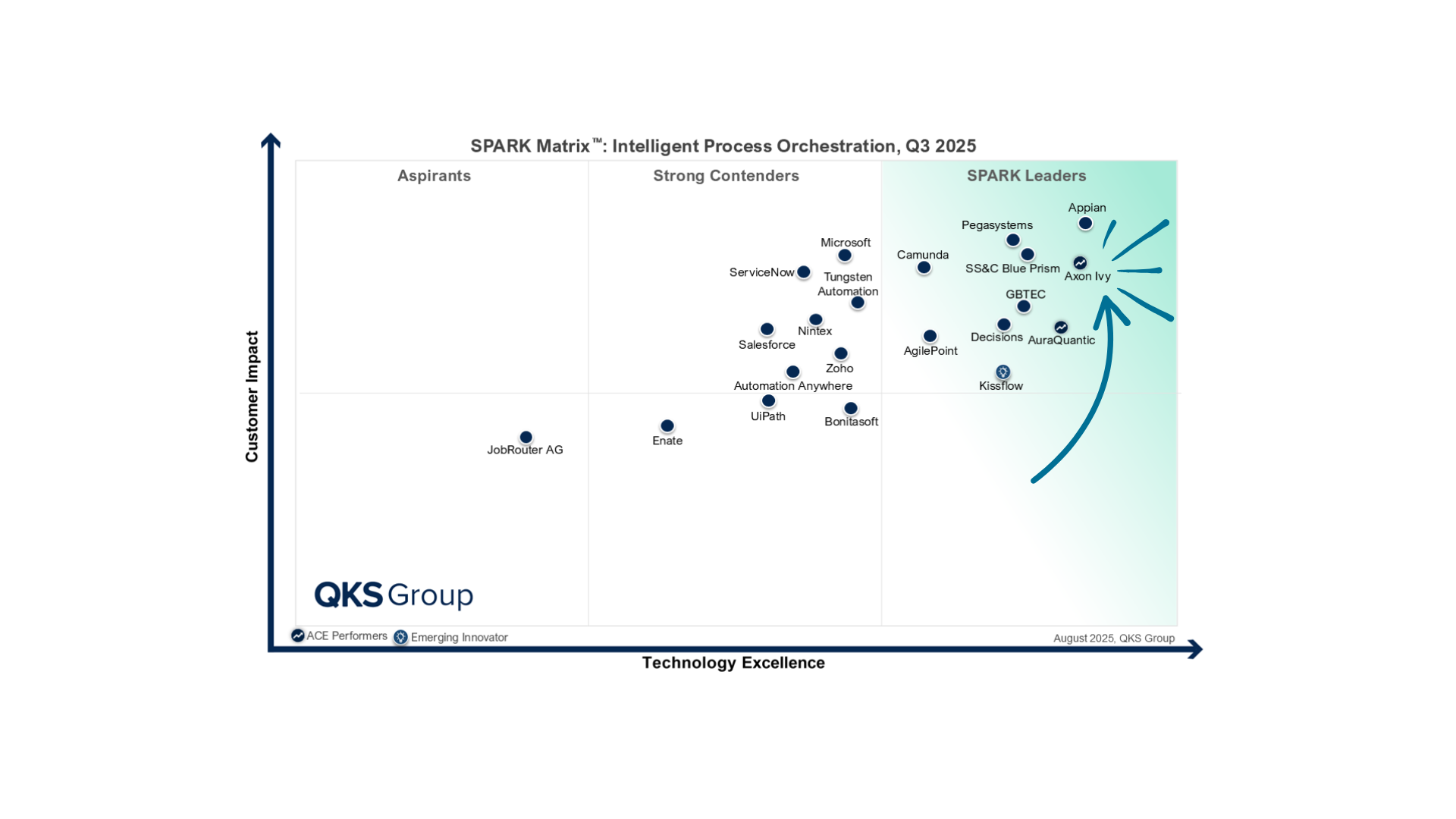

Axon Ivy: Technology Leader and Ace Performer in the 2025 SPARK Matrix

Axon Ivy has done it again! We have received two honors in the prestigious QKS Group SPARK Matrix™ Report 2025: Technology ...

Read more

Digitalization Requires More Than Just Projects

Why true digital transformation requires more than isolated initiatives and how the right balance between strategic ...

Read more