With Optimized Processes Towards Automation

Thinking and planning are essential for companies to defend and expand their market positions. However, relying solely on existing practices is insufficient for achieving long-term competitiveness. Companies need lean processes and efficient operations that save time and generate profits. Process optimization, as a fondation for automation, is a crucial step toward this goal.

The Starting Point: Process Potential Analysis (PPA)

The journey begins with a process potential analysis (PPA). This procedure involves identifying which processes are suitable for optimization and subsequent automation. PPA provides companies with a clear and transparent overview of their processes and value creation. It also highlights optimization potential and necessary changes for process automation.

Process Optimization

Once the most suitable processes are identified through the PPA, the next step is optimization. The aim is to digitize the processes as far as possible and prepare them for automation. This involves:

- Shortening throughput times

- Making optimal use of resources

- Increasing productivity

- Improving long-term quality

- Reducing costs and minimizing risks

For visualization, it has proven beneficial to sketch the processes graphically using the BPMN modeling standard. This method allows for the business process steps to be visualized from start to finish, creating easy-to-understand diagrams that can be shared.

A structured approach involves analyzing the current status of the process with the highest potential for digitization, building on the results from the PPA. Key questions to consider include:

- Who performs each task?

- How is the implementation executed?

- Which departments are involved?

- Which systems are utilized?

- How is the workflow structured?

Cross-departmental process thinking is essential to articulate the optimal process and identify possible weak points. A comprehensive understanding of these aspects provides an accurate picture of the current state.

“Since the optimization of processes is not a one-time task but a continuous process, the basis for continuous improvement is laid.”

Benedikt Diekhans

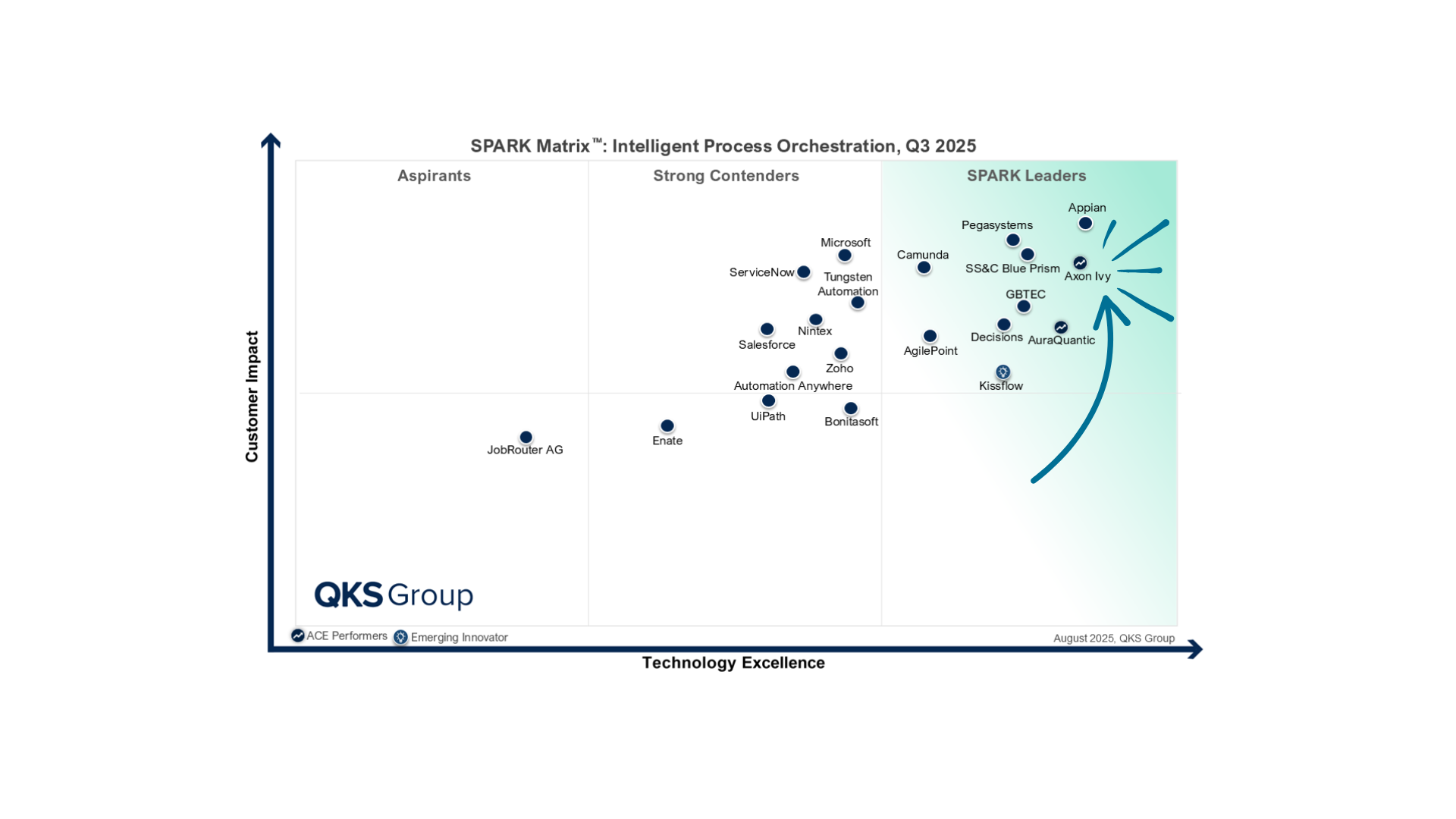

Key Account Manager, Axon Ivy AG

The Optimal Target State: (No) Wishful Thinking

After thoroughly analyzing the current state, the optimal target state is defined. Initially, this may involve "wishful thinking": rethinking, redesigning, and restructuring processes. Changes in procedures, adjustments in releases, and modifications of process chains play a pivotal role.

However, the description of the target process is only the beginning. Subsequently, it must be determined whether the ideas and suggestions can be implemented. This raises the question of technical implementation and whether the necessary technical prerequisites are already in place or still need to be established.

Testing Feasibility

To test implementation feasibility, a technical concept is required. This concept doutlines business and technical requirements, roles, and authorizations. It provides a solid framework for successfully digitizing a process. As with the PPA, involving all relevant departments and employees from the start is crucial. Active involvement in the decision-making and change processes can prevent resistance and rejection.

Continuous Improvement

Process optimization is not a one-time task but a continuous process, laying the foundation for continuous improvement, also known as the ongoing improvement process (CIP).

Conclusion

Process optimization and subsequent automation are crucial for companies aiming for long-term competitiveness. Starting with a process potential analysis, companies can identify areas for improvement and implement targeted optimizations. By involving all relevant stakeholders and continuously refining processes, companies can achieve efficient operations that save time and generate profits.